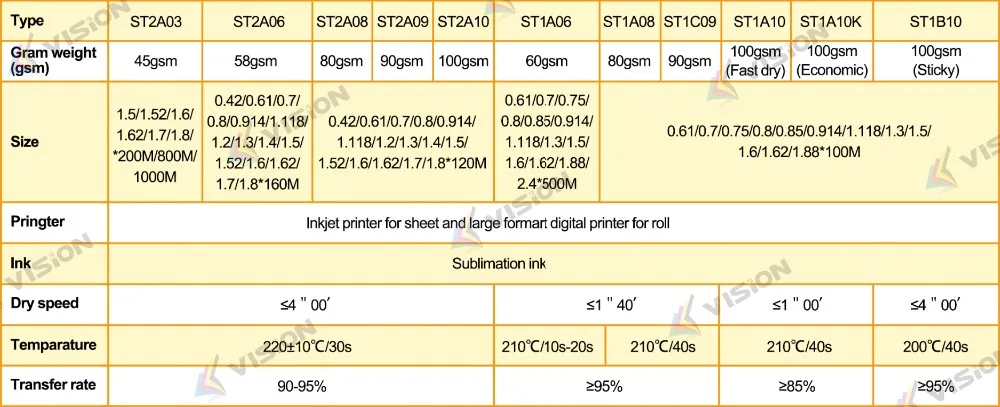

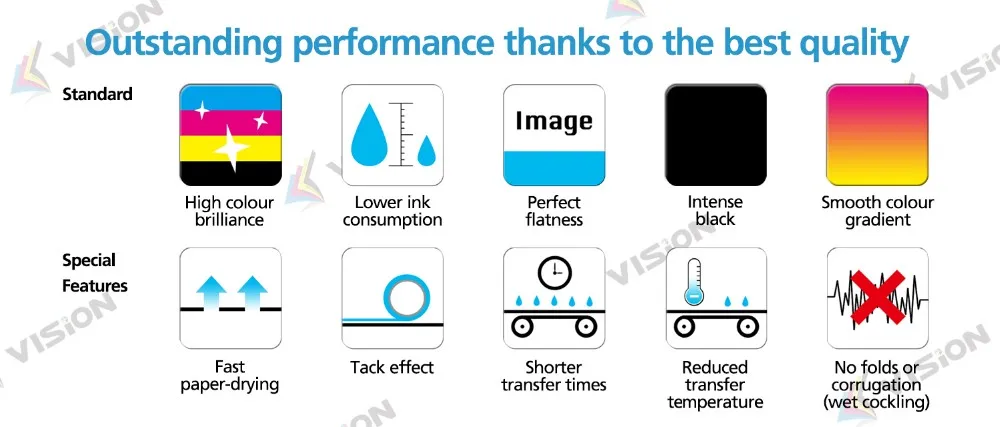

80g/90g/100g smooth surface/dry fast/heat transfer printing paper for textile

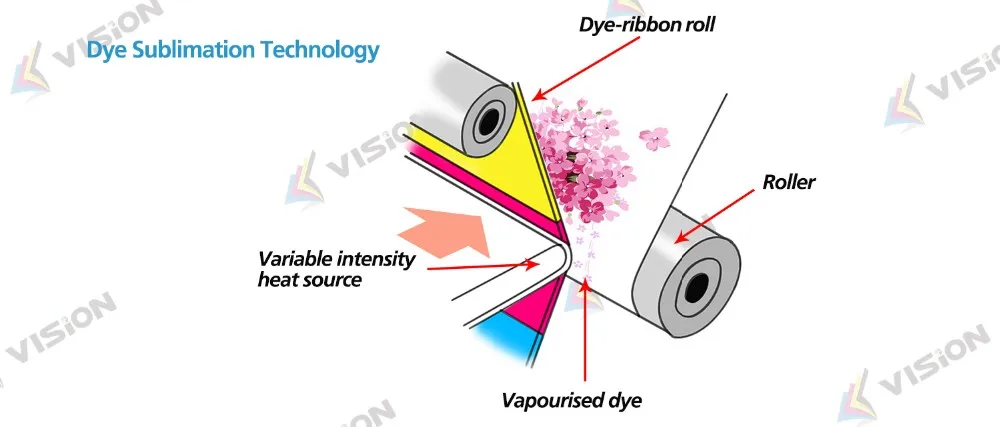

what is dye sublimation transfer paper

For dye sublimation transfer paper, fabrics historically had to be white or light in color. 100% polyester, poly/cotton mix (the garment should be at least 50% poly) microfibre and nylon can all be used. This printing process turns solid ink into a gas, avoiding a liquid stage. This process can be used on ceramic, wood, glass, or metal as long as they have a polymer coating.

Sublimation Transfer papers now exist for most textiles, including elastic fabrics used for making sportswear and swimming suits, and for natural fiber fabrics such as silk, linen, and wool.

Step 1.

Dye Sublimation refers to solid dye particles that are changed into gas using heat and pressure, which then bond with any polymers present and change back into a solid.

Step 2.

The Basic Dye Sublimation Process uses special heat sensitive dyes to print grahics and text onto special transfer paper. The paper is then placed on a Blank Sublimation product and both are placed in aheat press.

Step 3.

When the heating cycle is complete, the image on the heat transfer paper has been transferred to the item and has actually reformed into or underneath the coated surface. Run your finger across the surface of a sublimated photo mug, plare or any coated product and you will feel nothing. It is as smooth as anything.

Step 4.

The reason for this is that sublimation is alsways done on polyester, polymer - coated items. At high temperatures, the solid dye converts into a gas without ever becoming a liquid. The same high temperature opens the pores of thepolymer and allows the gas to enter. When the temperature drops, the pores close and the gas reverts to a solid state. It has now become part of the polymer.

Step 5.

This is why Dye Sublimation can't be done on natural materials such as 100% cotton or natural fibres and non coated materials which have no " pores " to open. Unless a polymer coated paper is used.

1.Low drying speed, what can we do to make it dry fast? What factors can influence the drying speed?

(1)The material of the paper

(2)The humidity of the printing environment

(3) How much ink the piezo head spray out

We can use the warmers and drying lights to quicken the process of drying

2.Which printer can be use ?

Our sublimation transfer paper can be used in any types of inkjet printer(Epson,Canon),as well as the large-format printer Like Roland, Mimaki,MS-JP

3.How to transfer low temperature Fabric?

The temperature of sublimation transfer if from 200℃ to 210℃. And for special fabric,the temperature of sublimation transfer should be under 200℃,you can adjust the temputure all by yourself according to the fabric.